From Ground Tests to Flight Confidence with Metal Additive Manufacturing

AndroMach is developing a 4-meter spaceplane designed to reach 200 km altitude and return to Earth, enabling up to five minutes of microgravity for scientific experiments.

To move the program forward, the team needed to validate a critical subsystem: the rocket engine.

Prototype Development & Ground Testing

Metal 3D Printing (EBM) + CNC Machining

High-temperature aerospace-grade metal alloy

Rocket engine ground demonstrator (combustion chamber and injector plate)

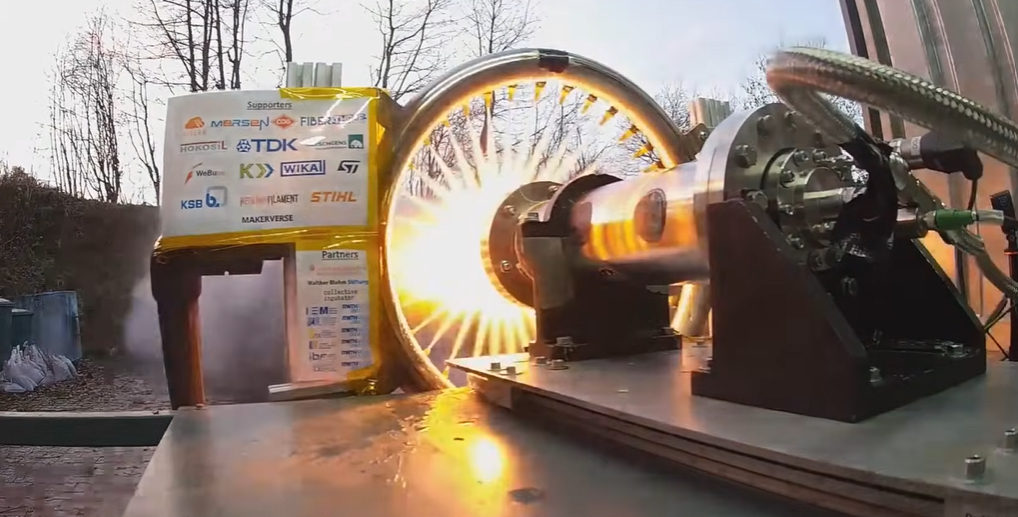

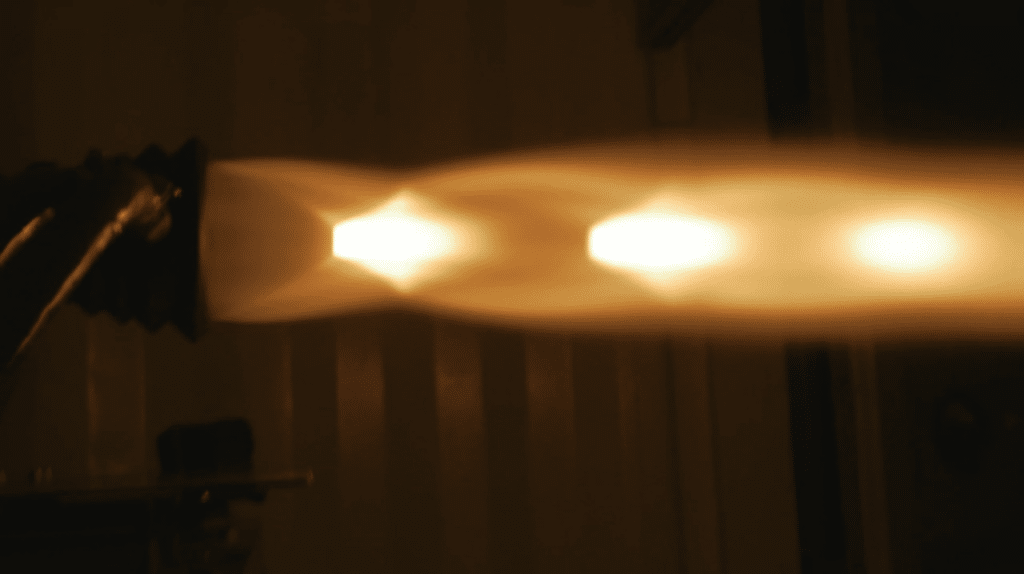

Successfully completed 20 hot-fire tests with over 300 seconds of cumulative firing time

Validated engine performance, reduced development risk, and accelerated the transition toward the optimized flight engine design with confidence from CNES.

AndroMach is developing a reusable spaceplane designed to reach 200 km altitude and return to Earth, enabling short-duration microgravity missions for scientific experiments.

At this stage, their priority was not full-scale production, but validating a critical subsystem: the rocket engine. To move forward toward flight, the team needed a ground demonstrator capable of delivering reliable performance data under real operating conditions.

Their focus was clear: test fast, learn quickly, and reduce development risk, while working with manufacturing partners capable of producing complex, high-performance aerospace components without slowing down the engineering team.

Credits : Gabriel Madignier

Working with MakerVerse gave us confidence that the components would be produced by manufacturers with the right experience in rocket engine applications and materials.

The engine performed extremely well during the campaign, successfully completing 20 hot-fire tests and accumulating more than 300 seconds of firing time. This allowed us to collect the data we needed and move forward toward the final flight engine design.

The decision was also supported by CNES, the French space agency funding the project.

Simon Allardet

Co-founder& Propulsion Engineer

The Challenge: Proving Performance Before Flight

The Challenge: Proving Performance Before Flight

AndroMach is developing a reusable 4-meter spaceplane designed to reach 200 km altitude and provide up to five minutes of microgravity for scientific experiments.

Before building the final flight engine, the team needed a ground demonstrator to validate the propulsion system under real conditions. The objective was to:

Collect performance data for design optimization

Validate thermal and structural behavior

Withstand repeated hot-fire tests

Produce complex internal geometries suitable for high-performance combustion

Speed was critical. The team needed qualified manufacturing capabilities without long supplier searches or coordination overhead that could slow down development.

Credits : Gabriel Madignier

The Solution: Metal Additive Manufacturing Built for Hot-Fire Conditions

The Solution: Metal Additive Manufacturing Built for Hot-Fire Conditions

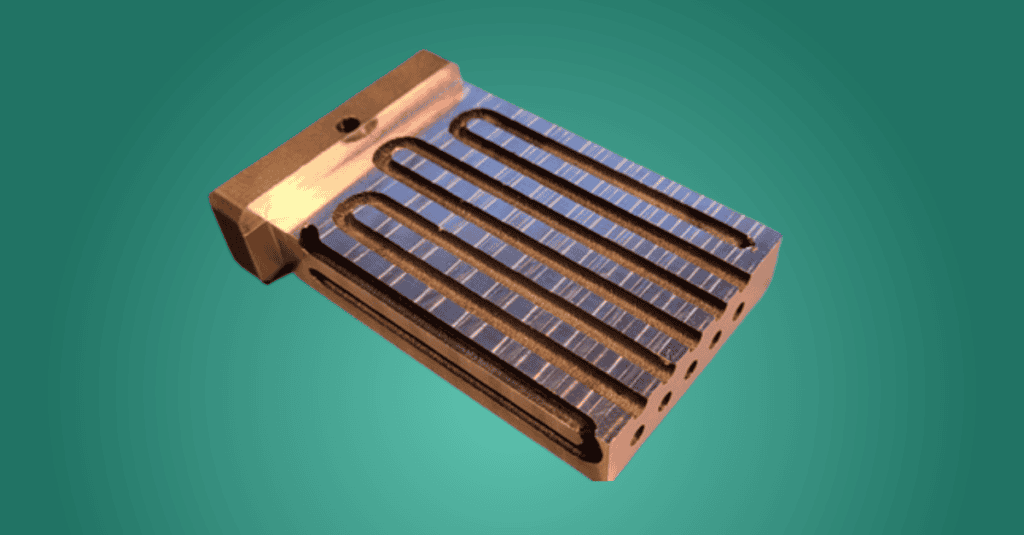

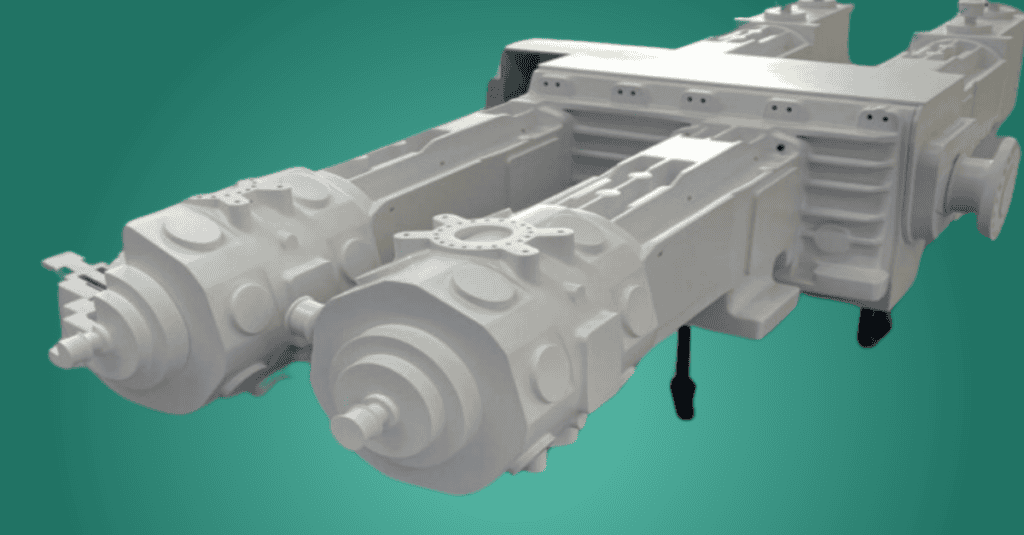

AndroMach used MakerVerse to manufacture the key engine components through advanced metal additive manufacturing combined with precision machining.

The project included:

Combustion chamber

Fully metal 3D printed and CNC-machined to final tolerancesInjector plate

Manufactured using EBM (Electron Beam Melting), followed by machining and precision drilling

Through MakerVerse, the team accessed experienced suppliers capable of producing high-performance aerospace components in the required material, without building and managing a specialized supplier network.

This enabled a fast production start and reliable execution for a critical development phase.

The Results

The Results

Validated Performance Under Real Conditions

20 successful hot-fire test attempts

More than 300 seconds of cumulative firing time

Stable and consistent engine behavior throughout the campaign

Clear Mach diamond patterns indicating healthy pressure and combustion performance

The test program delivered the operational data required to move forward with the optimized flight engine design.

Credits : Gabriel Madignier

Why It Matters

For aerospace development, the biggest risk is not design. It is whether critical hardware performs as expected under real conditions.

By enabling fast access to qualified manufacturing for complex metal parts, MakerVerse helped AndroMach:

Reduce technical and schedule risk

Accelerate the validation phase

Move faster from prototype to flight-ready design

Focus engineering resources on testing and optimization instead of supplier management

Other Use Cases

Want to speak with an expert?

Schedule a talk to help get your project started.