How GE-T Accelerated Innovation with the Felgen-Motte Project

GE-T is redefining the path from idea to market. By leveraging MakerVerse’s global manufacturing network, the innovation platform successfully launched their Felgen-Motte project with high cost-efficiency and minimal lead times.

Rapid Prototyping & Small Batch Production

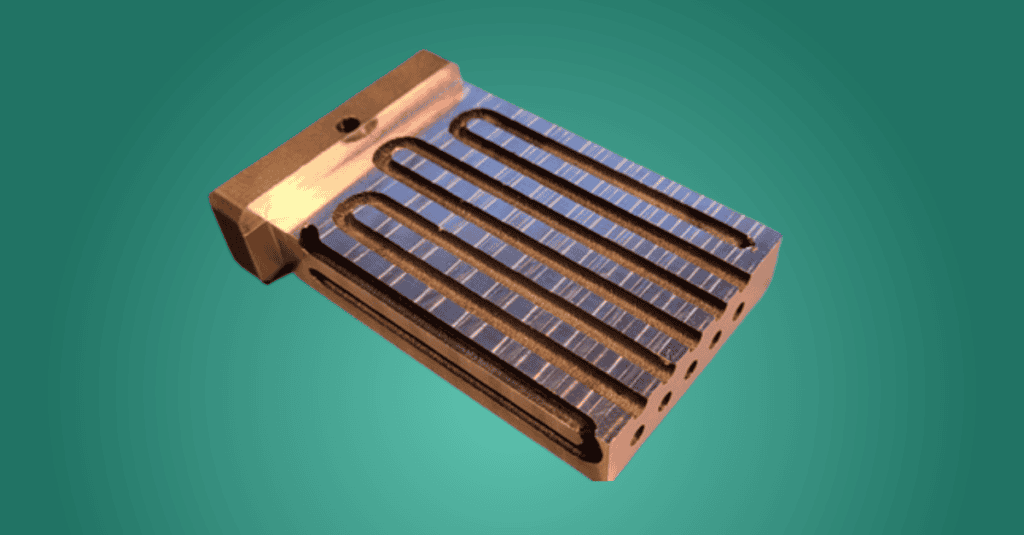

Injection Molding

Polyamid PA6

Felgen-Motte Project

Gained access to new manufacturing technologies and materials with industrial quality

Reduced coordination effort, faster turnaround than local toolmakers, and high cost-efficiency for initial launch.

GE-T (German Engineering & Technologies) positions itself as a powerhouse innovation platform. Their core mission is to bridge the gap between a visionary concept and a marketable product.

By focusing heavily on development and design, GE-T requires a manufacturing partner that can handle the complexities of production without the traditional overhead of intensive coordination.

Their priority is simple: turn ideas into real products without slowing down engineering with supplier management.

Working with MakerVerse enables us to quickly and efficiently turn ideas into marketable products. Access to a global network of modern manufacturing processes gives us the freedom to focus fully on developing and designing new products—while remaining highly cost-efficient.

Matthias Arndt

Lead Engineer at GE-T

The Challenge: Speed and Cost for Small Batches

The Challenge: Speed and Cost for Small Batches

For the Felgen-Motte project, GE-T faced a common industry hurdle: the “startup gap.”

When launching a new product with small initial batch sizes, traditional local toolmakers often present long lead times and high setup costs.

GE-T needed a solution that was:

- Pragmatic: A balance between high quality and cost-effectiveness.

- Fast: Shorter start-up periods to hit market windows.

- Low Friction: Minimal coordination effort to keep the team focused on design.

The Solution: A Pragmatic Experiment with MakerVerse

The Solution: A Pragmatic Experiment with MakerVerse

GE-T chose a deliberately pragmatic approach, treating the partnership with MakerVerse as a test of modern, platform-based manufacturing. By utilizing the MakerVerse platform, GE-T bypassed the manual “back-and-forth” of traditional procurement.

The implementation was carried out exactly to GE-T’s technical specifications. MakerVerse provided a seamless interface to a global network, allowing GE-T to source parts that met their rigorous functional requirements while staying within the budget constraints typical of an initial launch.

By uploading their designs and specifications, the team was able to:

- Access competitive pricing immediately

- Start production with a short ramp-up time

- Receive parts produced exactly as specified

- Avoid time-consuming supplier communication

Instead of managing multiple vendors, GE-T handled the project through a single platform and kept their focus on product development.

The Results

The Results

The “experiment” was a clear success. MakerVerse proved that platform-based sourcing could outperform traditional local options for this specific use case.

- Outperforming Local Toolmakers: In the Felgen-Motte project, MakerVerse delivered parts faster and more affordably than local alternatives.

- Operational Efficiency: The project required very little coordination effort, allowing GE-T to maintain a lean operation.

- Scalable Quality: The parts delivered were exactly as specified and “absolutely suitable” for the application, providing the necessary quality for a successful market entry.

- Cost-Efficient Launch: Small batch sizes—often a pain point for manufacturers—were handled efficiently, reducing the financial risk of the initial launch.

The Future of Innovation

By proving that MakerVerse can pass the “pragmatic test” for cost and speed, GE-T has secured a reliable partner for future innovations. For GE-T, MakerVerse isn’t just a supplier; it’s the manufacturing engine that grants them the freedom to innovate.

“Our decision to use MakerVerse was deliberately pragmatic… MakerVerse clearly passed this test.” – Matthias Arndt – Lead Engineer at GE-T

Other Use Cases

Want to speak with an expert?

Schedule a talk to help get your project started.