From Design Freeze to Flight Hardware: RWTH Aachen’s ASTRID Project

After design freeze, RWTH Aachen accelerated ASTRID’s transition from CAD to flight hardware using multi-technology manufacturing through MakerVerse.

Prototype Manufacturing & System Validation

CNC Machining, Metal & Polymer 3D Printing

Aerospace-grade metals and engineering polymers

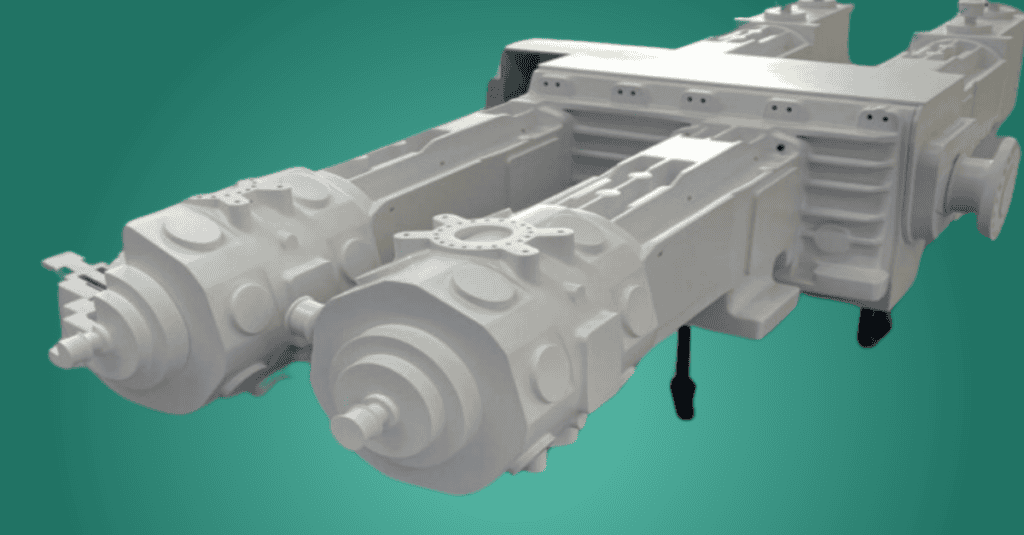

Structural components, propulsion elements, and system hardware for the ASTRID rocket

Transition from design phase to manufacturing and verification

Accelerated hardware readiness for testing and qualification toward EuRoC 2026

RWTH Aachen University’s Space Team is developing ASTRID, a student-built research rocket designed for the European Rocketry Challenge (EuRoC) 2026.

After completing the critical design review, the project entered its most demanding phase: turning detailed engineering into real hardware for manufacturing, testing, and system qualification.

Their priority was clear: move fast from finalized designs to physical components while minimizing sourcing complexity so the team could focus on integration, testing, and flight preparation.

Credit: RWTH Aachen Space Team

After completing our critical design review, the focus shifted to manufacturing and verification. Having reliable access to production allowed us to move quickly into hardware testing across multiple subsystems

Malte Schüttrumpf

Project Lead, Project ASTRID

The Challenge:

The Challenge:

From Final Design to Verified Hardware Under Tight Timelines

With the design phase completed, multiple subsystems needed to transition into manufacturing at the same time, including:

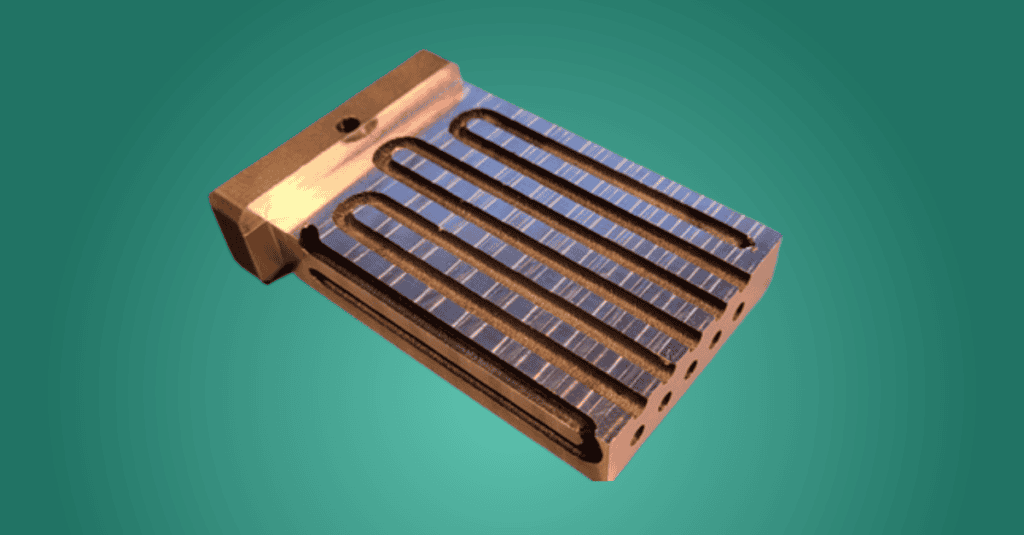

Structural components such as bulkheads, composite interfaces, and recovery hardware

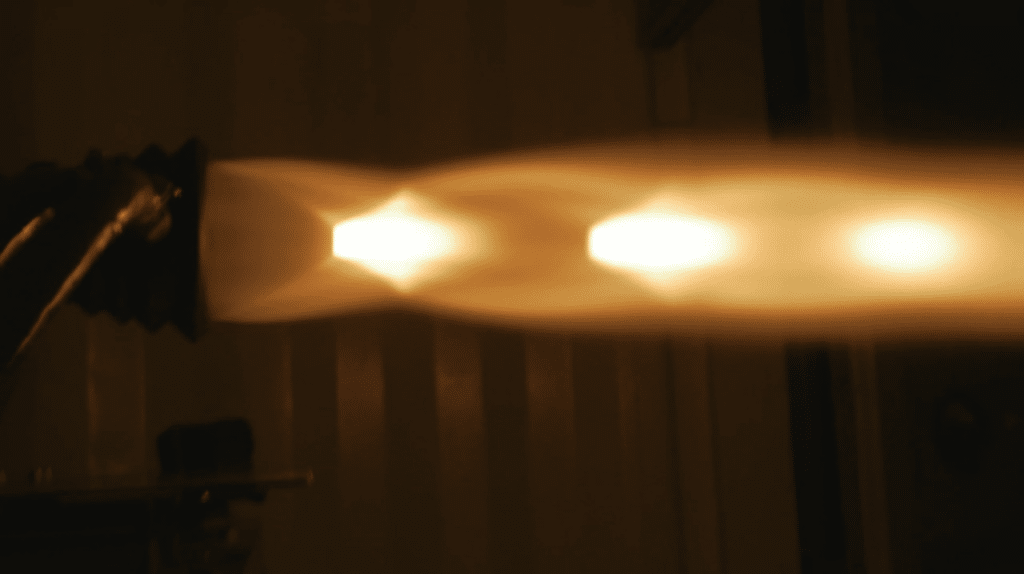

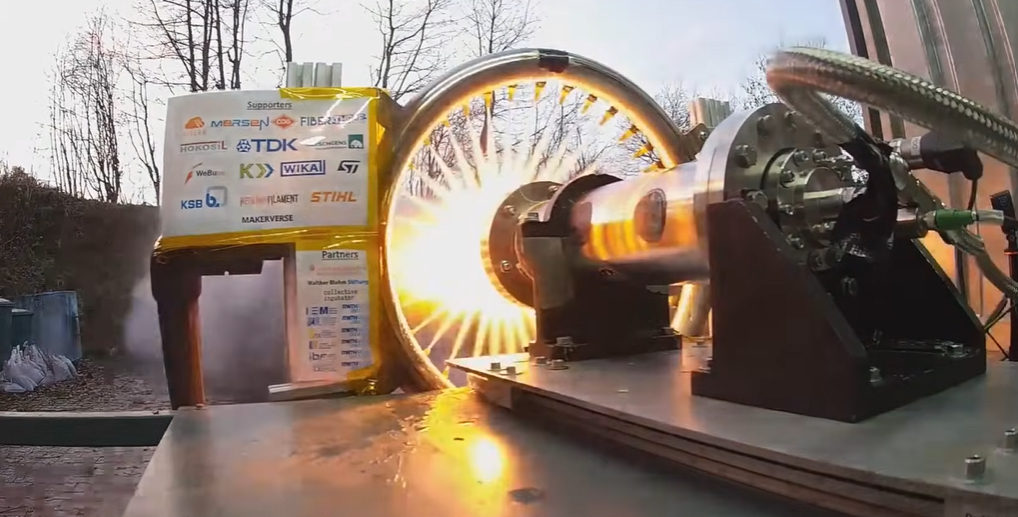

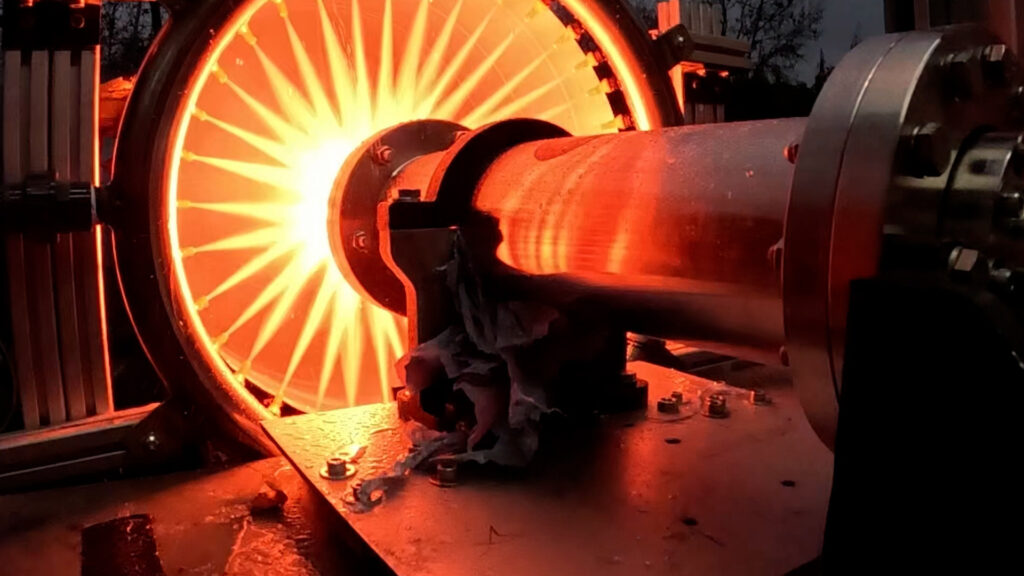

Propulsion system elements for hot-fire validation

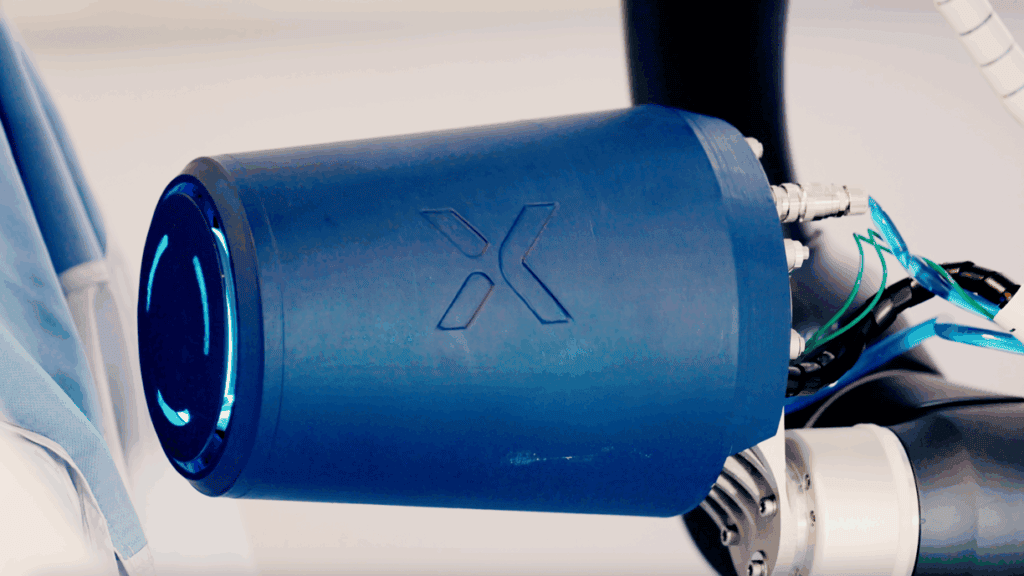

Avionics hardware and integration components

The team faced several constraints:

Limited time before qualification and flight milestones

Complex, high-performance geometries

Iterative development requiring fast production cycles

The need to coordinate multiple parts across different manufacturing processes

Managing multiple suppliers would have slowed progress and increased project risk.

Credit: RWTH Aachen Space Team

The Solution:

The Solution:

One Platform for Multi-Technology Prototype Manufacturing

The ASTRID team used MakerVerse to source critical components through a single platform, accessing CNC machining and additive manufacturing capabilities from a global supplier network.

This enabled them to:

Produce complex parts across multiple technologies

Reduce supplier coordination effort

Start manufacturing immediately after design finalization

Support rapid iteration as testing results informed design updates

By simplifying procurement, the engineering team could focus on system integration, testing, and verification instead of supplier management.

The Results

The Results

Hardware Progress Across All Major Systems

Following the critical design review:

Structural designs were finalized and prepared for manufacturing

Propulsion testing advanced, including successful hot-fire campaigns

Avionics hardware iterations were produced and tested

Recovery system design moved into manufacturing preparation

System verification activities began across subsystems

The project successfully transitioned from design to hardware development, a key milestone on the path to vehicle qualification and flight

Other Use Cases

Want to speak with an expert?

Schedule a talk to help get your project started.