The 10 Best Xometry Alternatives in 2026

The most important findings at a glance

- Quality over quantity: Open marketplace models such as Xometry offer maximum flexibility, but for B2B-critical process reliability, many industrial customers rely on alternatives with ISO certification and curated supply chains – such as Fictiv or MakerVerse.

- Engineering support instead of ticket systems: Automated platforms save time when it comes to standard parts. However, for complex projects, direct contact with manufacturing experts pays off. From feasibility analysis to quality approval, providers such as MakerVerse position themselves here as alternatives offering strong consulting services.

- The best Xometry alternative depends on your requirements: Protolabs scores highly for extreme speed, Formlabs for specialised 3D printing, and RapidDirect for cost-effective large-scale production. Those in the DACH region who want to combine technological diversity with European supply chains and competitive prices will find suitable options with providers such as MakerVerse or Hubs.

- The MakerVerse experience: The Berlin-based platform combines fast online quotes with real engineering support. You will receive binding prices within minutes. But even for complex projects, an experienced engineer is always on hand to assist you.

Start Your Manufacturing Project with MakerVerse

MakerVerse is a platform for sourcing industrial parts. It provides instant access to a vetted supply chain and a full range of manufacturing technologies. With AI-powered quoting, order management, and fulfilment, MakerVerse helps with everything from initial prototypes to full-scale production.

What matters in on-demand manufacturing

Choosing the right manufacturing platform determines the success or failure of your project. Whether CNC components, 3D parts or prototypes – each Xometry alternative has its own strengths. Those who compare suppliers based solely on price often overlook crucial factors such as delivery time, quality control, and personalised support. The following criteria will help you find the best platform for your manufacturing projects.

- Value for money and transparency of calculations: Online calculations should disclose all costs without hidden fees for components or post-processing. A transparent cost structure is crucial for objectively comparing the cost-effectiveness of different providers.

- Delivery times and reliability in meeting deadlines: Speed is important, but stability in delivery prevents costly delays in your projects. Also consider the organisational and time expenditure involved in preparing quotations and quality assurance.

- Available manufacturing technologies: Check whether CNC machining, 3D printing, injection moulding and sheet metal working are all available.

- Material and surface options: A wide range of materials and precise surface finishing are crucial for functional parts and prototypes with high requirements.

- Quality control and certifications: ISO certifications and documented quality checks ensure the precision of your components. This is particularly essential for series production. The integration of modern manufacturing platforms into ERP systems also enables seamless automation and improves quality assurance, which is particularly advantageous for companies with complex processes.

- Personal support vs. automated processes: Instant Quoting saves time, but for complex designs, customers need feedback from experienced engineers.

- Regional presence and supply chain optimisation: European manufacturers offer shorter delivery times and easier communication than global online manufacturers from China or the USA.

When selecting a suitable platform, you should consider various factors: Take into account the effort required for integration into existing processes, the cost structure and other factors such as quality and delivery time in order to make an informed decision.

The following comparison table shows you at a glance which Xometry alternative suits your needs.

The best Xometry alternatives for 2026 at a glance

The following table summarises the key differences between the leading online manufacturers, making it easier for you to choose the right Xometry alternative for your specific requirements.

| Supplier | Main strength | Technologies | Region | Instant Quoting | Price segment |

|---|---|---|---|---|---|

| MakerVerse | Best overall alternative with engineering support, broad network and flexible capacity | CNC, 3D printing, injection moulding, sheet metal, rapid casting | Europe (Germany, Austria, Switzerland, Benelux, United Kingdom) | Yes | Mid-range to premium |

| Protolabs | Fastest delivery times for prototypes, expansion into various areas of industrial manufacturing, strong customer support and discounts for large orders. | CNC, 3D printing, injection moulding | USA, Europe | Yes | Premium |

| Fictiv | Curated partner network with over 300 manufacturers, focus on rapid prototyping, small series, fast response times | CNC, injection moulding, 3D printing, urethane casting | Global (United States, China, India) | Yes | Premium |

| RapidDirect | Cost-efficient production in China, principle of the online marketplace | CNC, injection moulding, sheet metal, 3D printing | China (Shenzhen) | Yes | Low to Mid-range |

| Hubs | European subsidiary of Protolabs, specialising in CNC, sheet metal working and plastic injection moulding | CNC, 3D printing, injection moulding, sheet metal | Europe (Netherlands) | Yes | Mid-range |

| Star Rapid | Precision CNC and micro moulds, high surface quality, use in automotive and electronics industries | CNC, vacuum casting, injection moulding | China | No | Mid-range |

| Jiga | Marketplace with transparent cooperation with suppliers and partners, focus on individual characteristics and surfaces | CNC, sheet metal, injection moulding | Global | No | Mid-range |

| Zetwerk | Large-volume manufacturing from India, scalable capacity, discounts for long-term partners | CNC, casting, forging, sheet metal | If | No | Low |

| Geomic | UK-based with aerospace expertise, focusing on sophisticated CNC manufacturing, fast response times | CNC, 3D printing, injection moulding, sheet metal | UK, Europe | Yes | Mid-range to Premium |

| Shapeways | Industrial 3D printing with broad material and technology options | 3D Printing | Europe (Netherlands) | Yes | Premium |

In the following section, we present the five most important Xometry alternatives in detail and show which online manufacturer is the best choice for which manufacturing projects.

Detailed comparison of the top alternatives

The following five manufacturing platforms offer companies in German-speaking countries the best alternatives to Xometry – with different strengths in technologies, delivery times, and regional support for your CNC components and 3D parts. The following section explains in detail how the most important alternatives work in order to better understand the respective processes, the ordering process and the quotation process.

MakerVerse – The best overall alternative for industrial customers

MakerVerse is a European manufacturing platform headquartered in Berlin with a clear focus on industrial customers in Germany, Austria, Switzerland, Benelux and the UK. The platform combines instant quoting with personal engineering support and covers all major manufacturing processes – from CNC machining and 3D printing to injection moulding. Unlike many of its competitors, MakerVerse not only offers automated online quotes, but also direct contact with experienced engineers for complex projects.

- Instant quotes with AI-supported price calculation: The online calculation provides binding prices for CNC parts, 3D printing and other processes within minutes.

- Wide range of technologies: CNC manufacturing, additive manufacturing (SLS, MJF, LPBF), injection moulding, sheet metal working and rapid casting from a single source.

- Personal engineering support and DFM feedback: Experienced staff review designs for manufacturability and suggest optimisations – particularly valuable for prototypes.

- Quality control with fixed delivery dates: ISO-certified manufacturing partners and documented quality checks ensure the precision of your components.

- European supply chains for shorter transport routes: Regional manufacturing in Europe shortens delivery times and facilitates communication compared to global online manufacturers.

In additive manufacturing in particular, it is crucial for users to understand the specific properties of 3D-printed components in order to make the most of this technology and avoid errors.

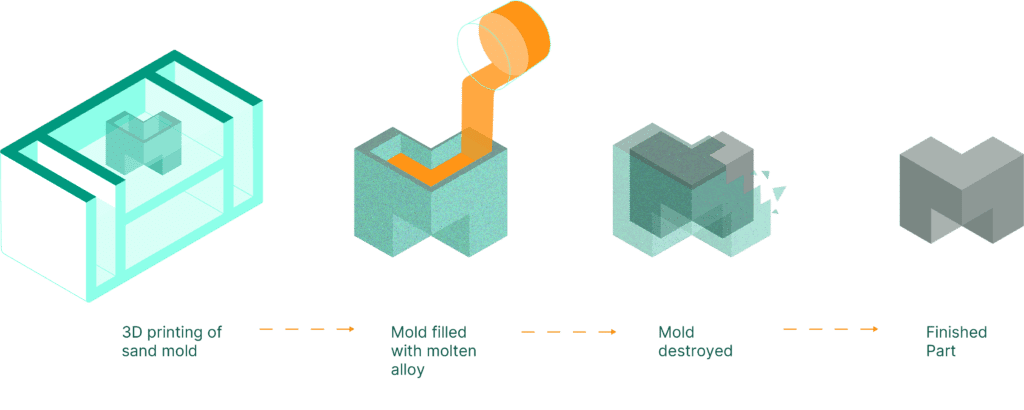

One special feature of MakerVerse is Rapid Casting for legacy parts – for example, when Siemens Energy needs spare parts for 100-year-old turbines. Instead of waiting months for traditional casting moulds, MakerVerse prints the sand moulds using 3D printing and delivers cast components in weeks rather than months. This expertise makes the platform the first choice for industrial customers with complex requirements.

The role of additive manufacturing at MakerVerse lies in flexible production, accelerating innovation and supporting users who want to develop new business models and applications.

Try MakerVerse Instant Quoting and receive a binding quote for your CNC components or 3D parts within minutes.

Protolabs – The fastest for rapid prototyping

Protolabs is an established US supplier focusing on maximum speed in the manufacture of prototypes and small series. The platform offers automated quoting with integrated DFM analysis and delivers CNC parts, in some cases within 1–3 days. For companies that require rapid iterations, Protolabs is a proven alternative to Xometry – albeit with premium prices.

Advantages:

- Fast delivery times: Standard CNC components and 3D parts often available in 1–3 days – ideal for urgent prototypes.

- Sophisticated online system with DFM analysis: The platform automatically detects manufacturing issues and suggests design changes.

- Wide range of materials: Extensive range of plastics, metals and surface treatments for various applications.

Disadvantages:

- Higher prices than European alternatives: Speed comes at a price – Protolabs is often 20–40% more expensive than MakerVerse or RapidDirect.

- Less personal support: Communication is mainly via automated systems, and direct contact with engineers is limited.

- Limited scalability for complex projects: Standardised processes reach their limits when it comes to larger series or technically demanding components.

Protolabs is best suited for companies that do not compromise on speed when it comes to rapid prototyping and are willing to accept higher costs in return.

Fictiv – The managed marketplace with curated partners

Fictiv is a US manufacturing platform with a global supplier network and a strong focus on quality control. The platform connects customers with a network of over 300 verified manufacturing partners worldwide, enabling a wide range of capabilities, high responsiveness and flexible production options – especially for rapid prototyping and small to medium series production. Fictiv takes care of the entire project management process, from quotation to final quality control. Compared to Xometry, Fictiv uses a premium pricing model with higher costs, but offers closer support for complex manufacturing projects.

Advantages:

- Over 300 certified manufacturing partners worldwide: Every supplier undergoes rigorous quality checks before manufacturing components for customers. The comprehensive network and close cooperation with reliable partners ensure high performance.

- Strong quality control and project management: Fictiv monitors every step of the manufacturing process and coordinates communication between customers and partners. Efficient customer support and collaborative partnerships ensure smooth operations and quick response times to enquiries.

- Good for precise CNC machining and injection moulding: Fictiv really shows its strengths when it comes to tight tolerances and complex designs.

Disadvantages:

- Premium pricing model with higher costs: The more personalised support and quality assurance are reflected in prices that are 15–30% higher than MakerVerse or RapidDirect.

Fictiv is suitable for companies that prioritise maximum quality and close support over price for critical projects and are willing to bear higher costs for this.

RapidDirect – The cost-effective China option

RapidDirect is a Chinese supplier with its own production facilities in Shenzhen and a clear focus on cost efficiency. The company offers CNC manufacturing, injection moulding, sheet metal working and 3D printing at significantly lower prices than its European or US competitors. Unlike many Chinese online manufacturers, RapidDirect operates its own factories, which enables better quality control than pure intermediary platforms.

Advantages:

- Highly competitive prices thanks to Chinese production: CNC components and 3D parts often cost 30–50% less than those from European suppliers such as MakerVerse or Protolabs. RapidDirect offers tiered discounts for large orders and can also cover high production volumes at short notice thanks to its flexible capacity.

- Own factories for better quality control: Unlike Xometry or Fictiv, RapidDirect manufactures directly in its own facilities rather than through third-party providers. The platform also enables integration with ERP systems, which supports seamless quality control and process automation, particularly for companies with complex manufacturing processes.

Disadvantages:

- Longer transport routes to Europe, possible customs delays: Shipping from China extends the total delivery time and can lead to unexpected delays during customs inspections.

RapidDirect is worthwhile for companies that are looking for maximum cost efficiency for larger quantities or less time-critical projects and are willing to accept longer transport routes in return. As a digital CNC manufacturer, RapidDirect offers better integration into existing business processes, higher automation and flexible capacities compared to traditional CNC manufacturers, which is particularly advantageous for digital online procurement and rapid scaling of manufacturing orders.

Hubs (Protolabs Network) – The hybrid platform with a global network

Hubs, operating under the name Protolabs Network since 2024, is a Dutch on-demand manufacturing platform headquartered in Amsterdam. Founded in 2013 as “3D Hubs,” the company was acquired by Protolabs in 2021 for $280 million and has since combined its own manufacturing capabilities with a global network of over 250 verified manufacturing partners. The platform offers CNC machining, 3D printing, injection moulding and sheet metal fabrication from a single source and is primarily aimed at engineers and product developers who need fast quotes and flexible manufacturing options.

Advantages:

- Combined hybrid model from our own factories and partner network: Protolabs Network combines in-house quick-turn manufacturing with a network of over 250 suppliers worldwide, enabling fast delivery times, volume pricing and expanded capabilities.

- Machine learning-based instant quotes: The platform compares uploaded CAD files with millions of previously manufactured parts and provides a quote within seconds. Around 98% of parts are priced automatically.

Disadvantages:

- Limited control over manufacturing partners: As production is handled by various network partners, quality can vary – customer reviews occasionally report inconsistencies in tolerances and surface quality between different manufacturers.

- Two separate platforms make usage difficult: Despite the integration, customers currently still have to use separate accounts for Protolabs (protolabs.com) and Protolabs Network (hubs.com), which complicates the ordering process.

Hubs (Protolabs Network) is particularly suitable for companies that require broad technology coverage and global manufacturing capabilities but do not expect intensive personal engineering support. The platform is a solid choice for standardised prototypes and small series where automated quotes and fast delivery times are paramount.

Manufacturing processes: From the idea to the finished component

The path from the initial idea to the finished CNC component is a structured process that requires maximum precision and state-of-the-art machinery. It begins with the development of the component: engineers and designers define all requirements and create a detailed design that is precisely tailored to the subsequent application. This design is then converted into a machine-readable format so that the CNC machines can manufacture the components with the highest precision.

During production, automated processes and advanced machinery ensure that each component meets the specified requirements precisely. Once production is complete, a comprehensive quality check is carried out to test the components for dimensional accuracy, surface quality and functionality. Only when all requirements have been met are the components delivered to the customer. There, they can be integrated directly into existing products or new applications – a smooth process that guarantees precision, reliability and customer satisfaction.

Start Your Manufacturing Project with MakerVerse

MakerVerse is a platform for sourcing industrial parts. It provides instant access to a vetted supply chain and a full range of manufacturing technologies. With AI-powered quoting, order management, and fulfilment, MakerVerse helps with everything from initial prototypes to full-scale production.

Xometry alternatives by use case: Which platform is right for your project?

- Rapid prototyping: Similar to Hubs with Instant Quoting, MakerVerse provides DFM feedback and direct contact with engineers for complex prototypes. European supply chains shorten delivery times compared to US or China-based suppliers

- Series production: For medium series (50–5,000 parts), MakerVerse offers framework agreements with fixed prices and staggered deliveries. For very large volumes of 10,000 parts or more, Zetwerk can offer cost advantages through Indian manufacturing.

- Industrial quality requirements: MakerVerse and Fictiv score highly with ISO certifications and documented test reports – essential for medical technology or aerospace. Fictiv is priced 15–30% higher.

- Europe-focused supply chains: MakerVerse (Berlin) and Hubs (Netherlands) enable complete manufacturing in Europe with shorter delivery times and easier communication.

Instant Quoting: MakerVerse combines AI price calculation with manual engineering review. Protolabs relies on full automation, while RapidDirect offers affordable online calculation with longer delivery times from China.

Decision aid: How to choose the right Xometry alternative

Choosing the right manufacturing platform determines the success, cost, and delivery time of your projects. The following questions and common mistakes will help you find the best Xometry alternative for your specific requirements.

Checklist: 7 questions to ask before choosing a platform

- Which manufacturing technologies do I specifically need? Check whether the platform covers CNC machining, 3D printing, injection moulding or sheet metal working – some online manufacturers specialise in individual processes.

- How important is personal engineering support to me? For complex components, you need direct contact with experienced engineers rather than just automated online calculations and standardised email responses.

- Do I need instant quotes or is manual calculation acceptable? Instant quoting saves time for simple CNC parts, but complex designs benefit from manual review by manufacturing experts.

- How critical are delivery times for my project? European suppliers often deliver CNC components 1–2 weeks faster than China-based online manufacturers – crucial for urgent prototypes.

- What is your budget? Compare not only unit prices, but also hidden costs for express delivery, post-processing, or quality checks for various Xometry alternatives.

- Are specific certifications required? ISO 9001, ISO 27001 or industry-specific standards are often indispensable in medical technology, aerospace or the automotive industry.

- Do I prefer European or global supply chains? Regional manufacturing shortens transport routes, reduces CO₂ emissions and facilitates communication – particularly important for series and recurring orders.

Avoid typical mistakes when selecting

- Focusing solely on price and neglecting quality and support: Cheap CNC components from China end up costing more if reworking is necessary or delivery times double.

- Selecting a platform without reviewing available technologies: Some online manufacturers only cover 3D printing – those who require CNC parts and injection moulding must coordinate multiple suppliers.

- Underestimate delivery times, especially with international suppliers: Production in China extends transport times by 1–2 weeks, and customs inspections can cause further delays.

- Overlooking hidden costs for reworking or express delivery: Instant Quoting often only shows base prices – surface treatment, quality control or faster delivery cost extra.

- Do not place a test order before undertaking larger projects: Small test orders demonstrate the quality, communication and delivery times of the Xometry alternative before you risk placing larger orders.

Start with a small test order from MakerVerse and check the quality, support and delivery time before placing larger manufacturing projects.

Who beats Xometry in on-demand manufacturing?

Xometry is not the only option for on-demand manufacturing – numerous specialised alternatives offer different strengths in terms of technologies, delivery times and regional support. While Protolabs scores with extreme speed, RapidDirect impresses with cost efficiency and Formlabs with 3D printing expertise. Each platform has its merits for specific manufacturing projects.

As a European manufacturing platform, MakerVerse offers the best balance of technological diversity, personal engineering support and cost efficiency for industrial customers in the DACH region. The combination of instant quoting for fast CNC components and 3D parts with direct contact to experienced engineers for complex designs makes the platform the first choice – especially if you value short delivery times, ISO-certified quality and European supply chains.

The right choice depends on your specific requirements – use the checklist in this article and test various Xometry alternatives with smaller projects before placing larger orders. This will help you find the online manufacturer that offers the best combination of price, delivery time, and quality for your components.

Get a free instant quote now at MakerVerse and compare prices, delivery times and material options for your CNC parts or 3D printing projects within minutes.

Start Your Manufacturing Project with MakerVerse

MakerVerse is a platform for sourcing industrial parts. It provides instant access to a vetted supply chain and a full range of manufacturing technologies. With AI-powered quoting, order management, and fulfilment, MakerVerse helps with everything from initial prototypes to full-scale production.

FAQ

What is the best alternative to Xometry in Europe?

MakerVerse is the best overall alternative to Xometry for Europe, headquartered in Berlin and focusing on Germany, Austria, Switzerland, Benelux and the UK. The platform combines instant quoting with personal engineering support and covers all major manufacturing processes – from CNC machining and 3D printing to injection moulding. European supply chains significantly reduce transport distances and delivery times compared to US- or China-based online manufacturers.

Which Xometry alternative is the most affordable?

RapidDirect offers the lowest prices thanks to Chinese production in its own factories – CNC components and 3D parts often cost 30–50% less than those from European suppliers. However, delivery times are longer due to shipping from China. As a European alternative to Xometry, MakerVerse offers a balanced price-performance ratio with shorter delivery times and regional support at moderate costs.

Are there any alternatives to Xometry that offer personalised support?

MakerVerse stands out thanks to its personalised engineering support – experienced staff check designs for manufacturability, provide DFM feedback and can be contacted directly by email or phone. Unlike purely automated platforms, you can speak directly to engineers about complex CNC components or 3D parts instead of just receiving standardised responses. Account management coordinates larger manufacturing projects with staggered deliveries.

Which platform offers the fastest delivery times?

Protolabs often delivers standard CNC components and prototypes in 1–3 days – ideal for urgent projects despite premium prices. MakerVerse offers delivery times of 3–10 days for CNC parts and 3D printing with European supply chains. RapidDirect produces quickly in China (3–5 days), but shipping to Europe extends the total delivery time to 2–3 weeks.

Can I also order series production from MakerVerse?

Yes, MakerVerse offers framework agreements for series of 50 to 5,000 parts with fixed prices and staggered deliveries over several months. These agreements secure your costs in the long term and guarantee delivery dates – particularly important for CNC components for mechanical engineering or the automotive industry. Project management includes Gantt charts, regular updates and personal contacts for larger manufacturing projects.

Which alternative is best suited for 3D printing?

As a pure 3D printing specialist with SLA, SLS and new 4L technology, Formlabs is the best choice for maximum precision in dentistry, jewellery or technical prototypes. As an alternative to Xometry, MakerVerse offers a broader spectrum with 3D printing (SLS, MJF, LPBF) combined with CNC machining and injection moulding – ideal if you need different manufacturing processes in one project.

Do Xometry alternatives also offer DFM feedback?

Yes, several providers offer design-for-manufacturing feedback: MakerVerse combines automated DFM checks with manual review by experienced engineers – particularly valuable for complex components. Protolabs integrates DFM analysis directly into its instant quoting system and automatically highlights manufacturing issues. Fictiv offers personalised engineering feedback through its curated partner network, but at higher prices than other Xometry alternatives.

How does instant quoting work at MakerVerse?

Upload your CAD file (STEP, STL, IGES) to the MakerVerse platform and select the manufacturing process, material and quantity. The AI-powered calculation system analyses the geometry, calculates machine time and provides a binding quote with price and delivery time within minutes. At the same time, engineers manually check complex designs and suggest optimisations. Try MakerVerse Instant Quoting now for free for your CNC components or 3D parts.