8 Design Tips for Better SLS 3D Printing

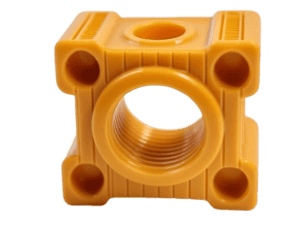

Selective Laser Sintering (SLS) has become one of our engineering team’s favorite 3D printing technologies, and for good reason. Its ability to produce durable, complex parts without supports makes it ideal for both prototypes and end-use components.

In this guide, we share 8 essential SLS design tips to help you achieve stronger, more accurate, and more manufacturable parts using the MakerVerse platform.

What Makes SLS Unique?

SLS 3D printing uses a laser to fuse layers of polymer powder, typically PA 12, PA 11, or filled composites, into solid parts. The unsintered powder surrounding the part acts as a natural support, enabling unmatched design freedom for internal channels, complex geometries, and even multi-part assemblies.

Compared to FDM or SLA, SLS delivers isotropic strength, satisfactory resolution, and consistent mechanical performance for functional applications across aerospace, robotics, and industrial manufacturing.

1. Optimize Wall Thickness

Thin walls risk warping or cracking, while overly thick walls retain heat and can distort.

Rule of thumb: Keep walls between 0.7–2.0 mm and maintain consistency throughout. For added stiffness, use ribs instead of thicker walls.

2. Add Escape Holes for Powder Removal

Because SLS leaves unsintered powder inside cavities, parts must include escape holes for cleaning.

Best practice: Add at least two holes ≥ 3.5 mm on opposite sides to ensure complete powder evacuation and smoother post-processing.

3. Design Channels and Holes Correctly

Round holes often shrink by 3–4 % during sintering.

Tip: Oversize holes slightly or use standard drill diameters for easy reaming. For long internal channels, use tear-drop or diamond shapes for strength and better airflow.

Start Your Manufacturing Project with MakerVerse

MakerVerse is a platform for sourcing industrial parts. It provides instant access to a vetted supply chain and a full range of manufacturing technologies. With AI-powered quoting, order management, and fulfilment, MakerVerse helps with everything from initial prototypes to full-scale production.

4. Ensure Clearance for Mating Parts

Printing, moving, or interlocking assemblies is possible with SLS—but only if clearances are correct.

Guidelines:

Mating parts: ≥ 0.7 mm gap

Press fits: 0.5 mm

Linked parts: 0.6 mm

5. Avoid Unsupported Spans

SLS doesn’t need supports, but long bridges can still sag.

Design tip: Keep overhangs below 45°. Use arches, chamfers, or fillets to distribute stress and maintain surface quality.

6. Size Small Details Properly

Fine text or logos can disappear during the finishing process.

Recommendation: Use at least 1 mm height/depth and fonts ≥ 2 mm for readability after bead blasting. Sans-serif fonts yield the cleanest results.

7. Reinforce Long or Thin Features

Slender pins and walls can deform under heat or during post-processing.

Minimum pin diameter: 0.8 mm (1 mm preferred).

Add ribs or gussets to connect thin features to larger sections and orient parts to minimize unsupported height.

8. Account for Shrinkage and Tolerances

SLS parts shrink slightly during cooling, typically 3–4 %.

Tolerance: ± 0.3 mm or ± 0.3 %.

Apply tight tolerances only where needed to avoid unnecessary cost or rework.

SLS at MakerVerse

Every SLS project at MakerVerse runs through automated manufacturability checks and a network of verified suppliers.

Upload your CAD file, compare real-time pricing, and get transparent lead times before production even begins.

Learn more about our SLS 3D printing services or explore PA 12 material properties to choose the best fit for your project.

SLS combines freedom of design with industrial-grade performance, but great results start with innovative design.

By following these eight tips, you’ll reduce rework, improve accuracy, and get production-ready parts faster through MakerVerse.

Upload your design today and see how MakerVerse brings your parts to life.