Order CNC Milled Parts Online: Calculate Precise Manufacturing in Minutes

The most important findings at a glance

- Instant Quote Instead of Waiting Time: Online calculation delivers binding prices and delivery dates in minutes, not after multi-day quote requests via email.

- Full Transparency from the Start: All costs, delivery times and technical parameters are directly visible – no hidden fees or subsequent price adjustments.

- Broad Technological Spectrum: From 3-axis to 5-axis milling, over 300 materials like aluminum, steel, stainless steel and plastic available for every requirement.

- Intelligent Decision Support: MakerVerse offers a material advisor that supports you in selecting suitable materials and technologies for your CNC milled parts.

- Efficiency for Buyers and Engineers: Up to 50% time savings in the procurement process through digital processing and access to qualified manufacturing partners from a network.

Start Your Manufacturing Project with MakerVerse

MakerVerse is a platform for sourcing industrial parts. It provides instant access to a vetted supply chain and a full range of manufacturing technologies. With AI-powered quoting, order management, and fulfilment, MakerVerse helps with everything from initial prototypes to full-scale production.

Why Order CNC Milled Parts Online?

Traditional procurement of CNC milled parts costs time and nerves: emails to various suppliers, multi-day waiting times for quotes, lack of price transparency and the laborious coordination of multiple manufacturing partners. Anyone looking for a reliable CNC milled parts supplier quickly loses track of costs and availability. On-demand manufacturing makes this process more efficient and plannable.

- Instant Quote in Minutes: Instead of waiting days for responses, you receive binding prices and delivery dates within minutes after uploading your CAD file.

- Transparent Costs and Delivery Times: All relevant information is visible from the start – no hidden fees, no subsequent price adjustments, full planning security.

- Access to Broad Manufacturing Network: An online manufacturer connects you with qualified manufacturing partners covering various technologies and materials – everything from a single source.

- Supplier Consolidation: Reduce the number of your suppliers and simplify your procurement processes through central processing via one platform.

- Up to 50% Time Savings: Digital CNC manufacturing significantly accelerates the entire procurement process – from inquiry to delivery.

These efficiency gains make online ordering of CNC milled parts the preferred solution for modern procurement departments and engineers.

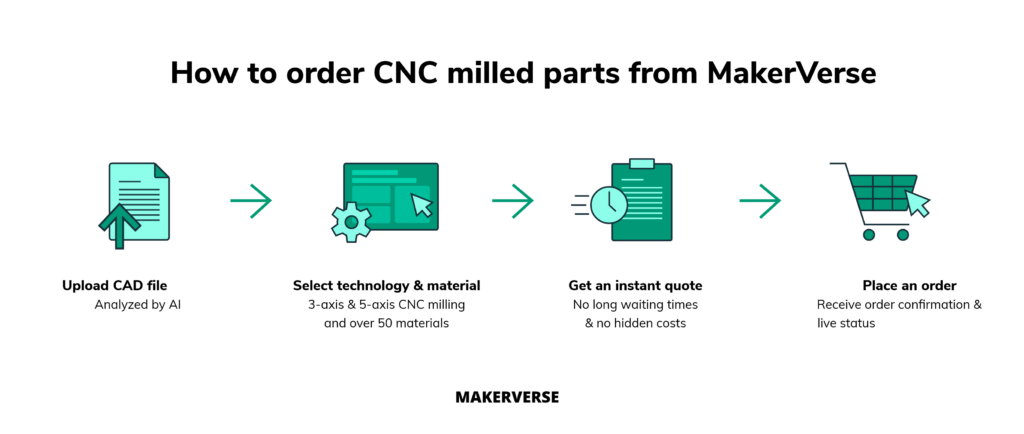

How Online Ordering Works at MakerVerse

Ordering CNC milled parts online at MakerVerse is completed in just a few steps. The entire process is designed so that you quickly and easily get your binding quote.

Upload CAD File

Upload your CAD model or your technical drawing directly to the platform. MakerVerse supports common file formats like STEP, STL, SLDPRT, CATPART and IPT. Your data is transmitted encrypted and treated confidentially – data protection and security have highest priority. The upload process takes only a few seconds, regardless of the complexity of your components.

Select Technology and Material

Choose from various milling technologies: from cost-efficient 3-axis milling for simple geometries to 5-axis machining for complex components. For materials, you have metals like aluminum, steel, stainless steel and copper as well as technical plastics available. Not sure which material is optimal? The material advisor helps with selection and recommends suitable materials based on your requirements.

Receive Instant Quote

Within minutes, the system analyzes your CAD file and creates a binding quote with fixed price and delivery date. This online calculation is transparent and without hidden costs. If the automatic price doesn’t meet your expectations, you can specify a target price – MakerVerse then manually checks whether this is feasible. Manual review by engineers for optimization suggestions is also possible.

Place Order

After reviewing the quote, you confirm the order with just a few clicks. Payment is made securely via the platform, then you can track the status of your CNC parts online at any time. For questions, a personal contact person is available – via email or by phone during business hours.

Delivery Times and Costs: Transparency from the Start

Planning security is crucial in the procurement process. Anyone ordering CNC milled parts online wants to know from the start when the parts will be delivered and what they cost. MakerVerse offers this transparency through binding delivery dates and fixed prices without subsequent adjustments or hidden fees.

| Aspect | Traditional Procurement | Online Ordering at MakerVerse |

|---|---|---|

| Quote Time | 3–7 days waiting time | Instant quote in minutes |

| Price Transparency | Often unclear, subsequent adjustments possible | Fixed price immediately visible |

| Delivery Time | Variable, often non-binding | Binding delivery date from order |

| Changes | Complicated, requires new inquiries | Easily adjustable via platform |

The typical delivery times for CNC milled parts at MakerVerse are between 3 and 15 days, depending on the complexity of the component and the selected technology. Costs are influenced by several factors: material choice (aluminum is cheaper than titanium), geometric complexity, required tolerances and desired surface treatment. Compared to traditional processes, you save up to 50% time from inquiry to delivery of your milled parts.

Materials for CNC Milled Parts: Making the Right Choice

The material choice significantly influences the functionality, durability and costs of your CNC milled parts. Each material brings specific mechanical and chemical properties that must match the application. A well-founded decision avoids later problems and optimizes the price-performance ratio.

- Aluminum: Lightweight, corrosion-resistant and excellently machinable – ideal for housings, brackets and components where weight matters.

- Steel: Offers high strength and versatility at moderate costs – proven for resilient components in mechanical engineering and automation technology.

- Stainless Steel: Combines corrosion resistance with hygienic properties – first choice for medical technology, food industry and chemically stressed environments.

- Copper: Outstanding electrical and thermal conductivity – indispensable for electrical contacts, heat sinks and electronic components.

- Plastic: Lightweight, chemical-resistant and cost-effective – suitable for prototypes, insulating parts and applications without extreme mechanical stress.

MakerVerse provides over 270 materials and guarantees constant availability for your entire project. The material advisor analyzes your requirements and automatically recommends suitable metals or plastics – based on technical parameters such as strength, temperature resistance and surface properties. This way you quickly make the optimal material choice for your CNC milled parts.

Start Your Manufacturing Project with MakerVerse

MakerVerse is a platform for sourcing industrial parts. It provides instant access to a vetted supply chain and a full range of manufacturing technologies. With AI-powered quoting, order management, and fulfilment, MakerVerse helps with everything from initial prototypes to full-scale production.

From 3-Axis to 5-Axis: Which Milling Technology Do You Need?

The choice of milling technology determines complexity, precision and costs of your CNC milled parts. While simple geometries are cost-effectively manufactured on 3-axis machines, demanding components require the extended capabilities of 5-axis machining.

3-Axis Milling

With 3-axis milling, the tool moves along the X, Y and Z axis – horizontally, vertically and into depth. These CNC milling machines are cost-effective to operate and deliver fast results for flat surfaces, grooves and vertical holes. Typical applications include simple housings, plates and brackets. A natural limitation: inside corners are always rounded because the cylindrical milling tool cannot create sharp corners. For complex three-dimensional shapes, the technology reaches its limits.

5-Axis Milling

5-axis milling machines expand the spectrum through two additional rotation axes that position the tool or workpiece at any angle. These 5-axis CNC milling machines enable manufacturing of complex geometries and curved shapes in a single operation – without time-consuming re-clamping.

CNC milling becomes more precise as positioning errors are minimized through fewer clamping operations. Higher machine costs are compensated by significant time savings for demanding components. Applications range from turbine blades to medical implants to complex prototypes in aerospace.

As decision support: Choose 3-axis for flat or simple milled parts, 5-axis for complex three-dimensional geometries or when tight tolerances are required on multiple machining sides. MakerVerse automatically analyzes your uploaded CAD file and recommends the suitable technology for optimal quality and economy.

Conclusion: Order CNC Milled Parts Online with MakerVerse

Online ordering of CNC milled parts combines digital efficiency with technical expertise. MakerVerse delivers instant quotes in minutes instead of multi-day waiting times, transparent costs without hidden fees and binding delivery dates for maximum planning security.

The broad spectrum ranges from 3-axis to 5-axis milling, over 300 materials from aluminum to plastic are constantly available. Despite the digital platform, personal contacts remain accessible – for technical support on complex projects or optimization suggestions from experienced engineers. Quality is ensured by ISO 9001-certified manufacturing partners, certifications and test reports are available upon request.

Upload your CAD file now and receive a non-binding instant quote – experience how simple modern CNC manufacturing works.

Start Your Manufacturing Project with MakerVerse

MakerVerse is a platform for sourcing industrial parts. It provides instant access to a vetted supply chain and a full range of manufacturing technologies. With AI-powered quoting, order management, and fulfilment, MakerVerse helps with everything from initial prototypes to full-scale production.

FAQ

Which CAD file formats are accepted for online ordering?

MakerVerse supports all common CAD file formats for CNC machining. STEP and STL are recommended as they are universally compatible. Other accepted formats are SLDPRT, CATPART, IGES, IPT, PRT, 3DXML and JT. You need both a 3D model and a technical drawing with all relevant tolerance specifications. The CAD file is automatically analyzed after upload to create a precise instant quote for CNC milling.

Can I specify a target price if the instant quote is too high?

Yes, MakerVerse offers the target price function. If the automatic quote exceeds your budget, you can specify a desired price. Our engineers then manually check whether this price is feasible through optimizations in material, technology or design – without loss of quality. This applies to both CNC milled parts and CNC turned parts. You receive a realistic assessment of whether and how your costs can be reduced before placing the order.

How are tolerances ensured for online ordered CNC milled parts?

All manufacturing partners of MakerVerse are ISO 9001-certified and comply with industry standards such as ISO 2768 and ISO 286. Before shipping, your CNC milled parts undergo multi-stage quality control with modern measurement technology (Zeiss, Keyence, Mitutoyo). Manufacturing focuses on consistency (reliability) – parts are produced in three months exactly as they are today. Certifications and detailed test reports (CMM, FAIR) are available upon request and document compliance with all tolerances.

Can I receive technical consultation for complex geometries?

Yes, personal contacts and technical engineers are available for complex requirements. You can reach the team Monday to Friday from 7 AM to 6 PM by phone or anytime via email. For demanding geometries, you can select the “Manual Review” option – experienced engineers analyze your CAD file and provide DFM feedback (Design for Manufacturing) with concrete optimization suggestions for better manufacturability or lower costs. This applies to both CNC machines with 3-axis and 5-axis machining.